Technology

Mema Engineering Team

1/5/2025

7 min read

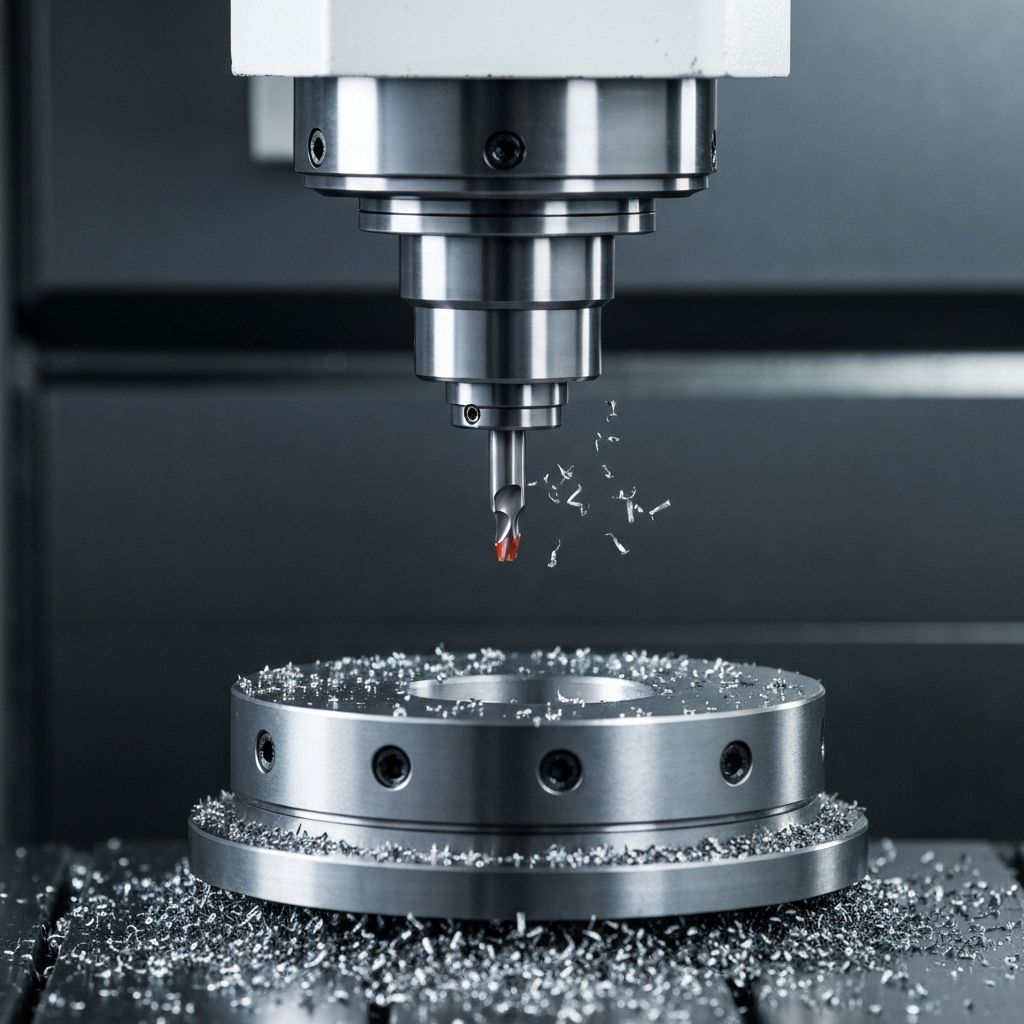

CNC Machining: The Future of Precision Gear Production

Computer Numerical Control (CNC) machining has revolutionized gear manufacturing, enabling unprecedented precision, repeatability, and efficiency. At Mema Engineering, we utilize state-of-the-art 3-axis CNC turning and milling equipment to produce gears that meet the most demanding specifications.